Contactless Candy Dispenser

Objective Summary

For my Introduction to Mechanical Engineering Class: build a prototype for a Covid-safe dispenser for small candies. Candy amounts should be consistent for each dispense. See video below:

Further Background

This was the final quarter project for my introduction to mechanical engineering class; we had only 2-3 weeks for the project. I was in a group with 2 other members. We delegated the work so that I would CAD and assemble the machine and they would work on the presentation aspects. At this point in time, most of my classmates had very minimal technical experience with CAD or building things in general. However, I already had a significant amount of background with such skills, so I wanted to go above and beyond with this project. While most people in the class chose to construct their project out of cardboard, foam, and hot glue, I wanted to go one step further. My device was to be 3D printed with electromechanical actuation.

Process

I designed this machine to operate in a manner similar to a contactless hand sanitizer dispenser. Once a hand is detected within a certain distance from a sensor, a fixed amount of product is deposited.

Candies rest upon the top storage compartment “hopper” of the machine. Once a hand is placed underneath the hopper, it is detected by an ultrasonic sensor that opens a small “trap door” underneath the hopper for a fixed amount of time (a fraction of a second) to allow a consistent amount of candies to fall through.

Seen here: a test using some basic code to operate the Arduino portion of this device.

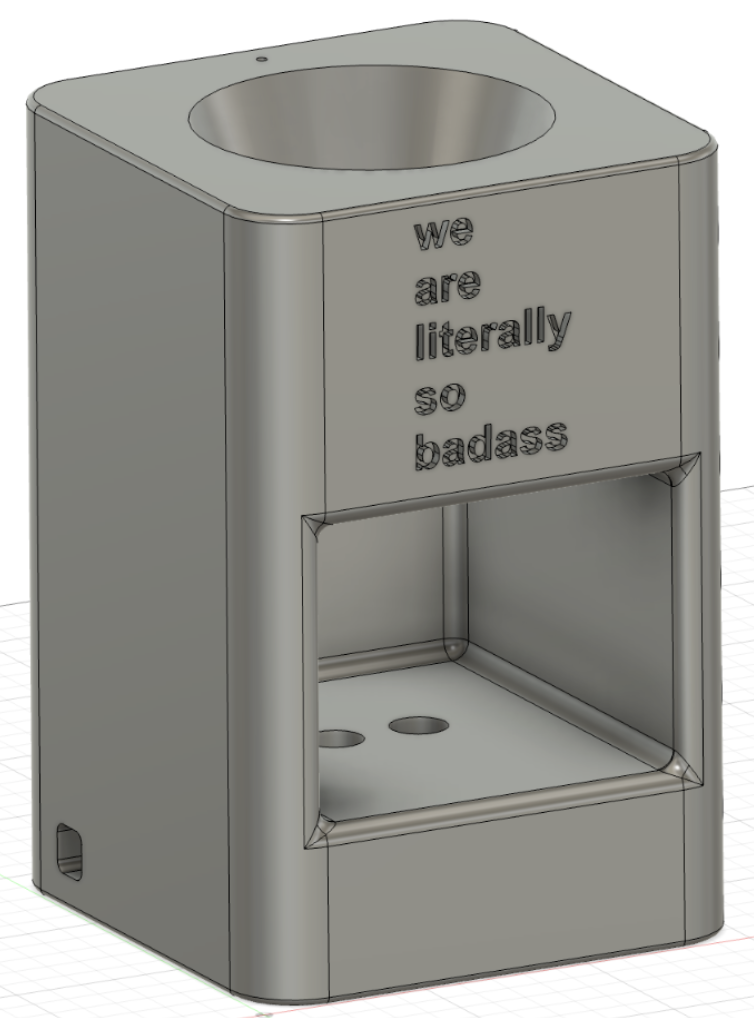

Seen here: I designed the device so that it could almost entirely be 3D printed in one piece. There are just two small separately printed components: a small plastic trap door attached to the servo and a plastic panel underneath that houses the Arduino Uno.

The servo is screwed into the top (right above the opening for the hand, right behind the text on the front) while the Arduino and ultrasonic sensor sit underneath (right below the opening for the hand, underneath the two holes for the sensor).

A clear plastic half of a Christmas tree ornament is used as the dome window to view the candies. It swivels to the side to allow candy to be refilled once the machine’s supply is depleted.

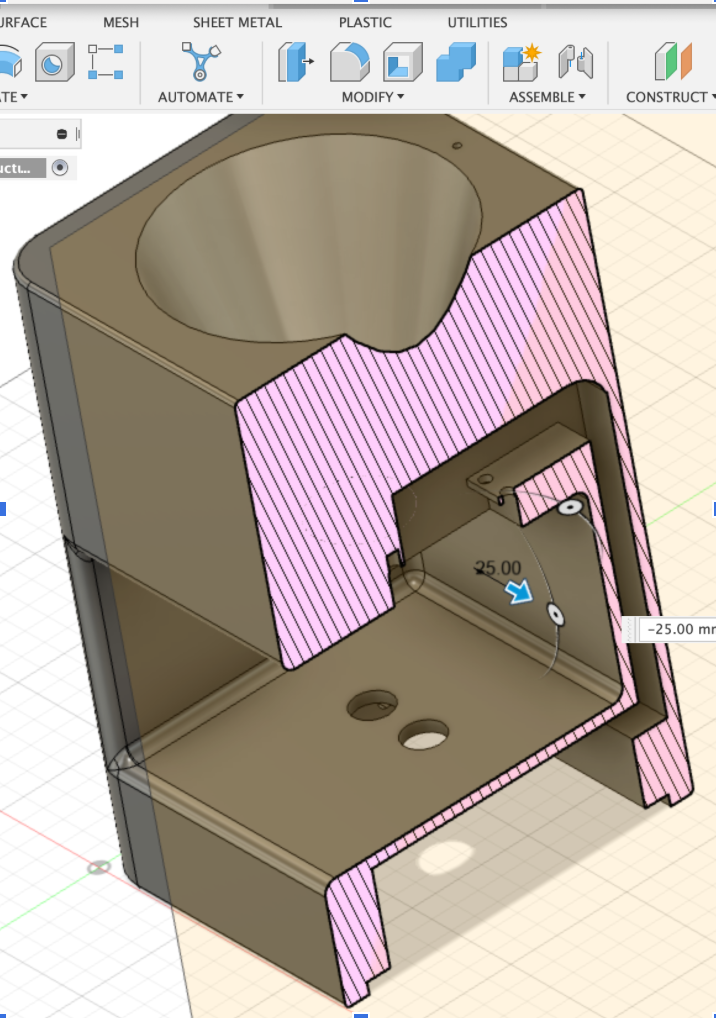

Seen here: I had to route an internal tunnel through the back of the machine so that the servo motor wire at the top could plug into the Arduino at the bottom. This sliced section view in CAD shows the internal tunnel that the servo wire takes; it is completely unnoticeable from the outside. The wire is fished through and connects the servo at the top gap to the Arduino in the bottom gap.

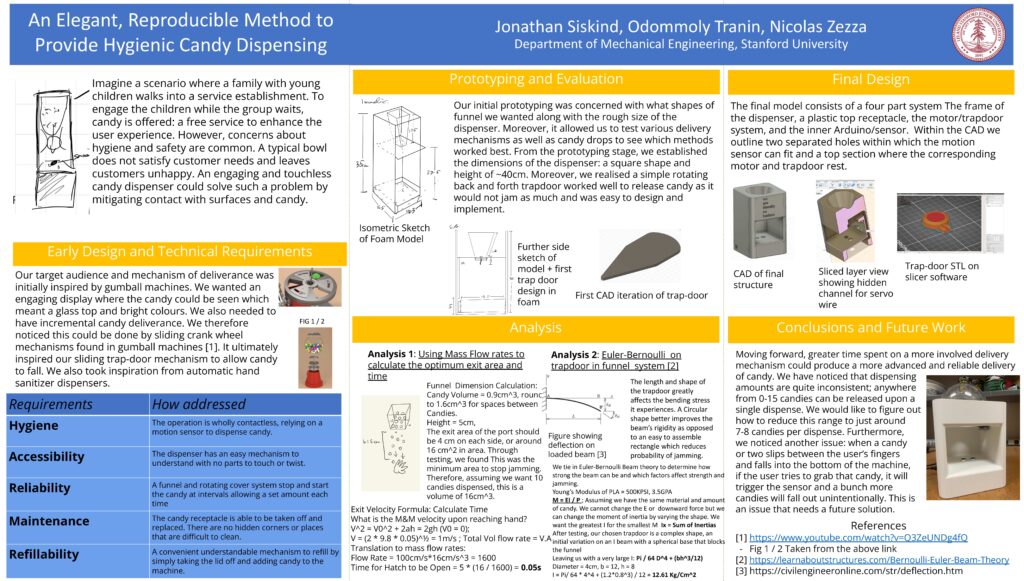

Poster

Seen below: my group’s poster for the end-of-class poster session.